Cranial calvaria - PEI-Ultem

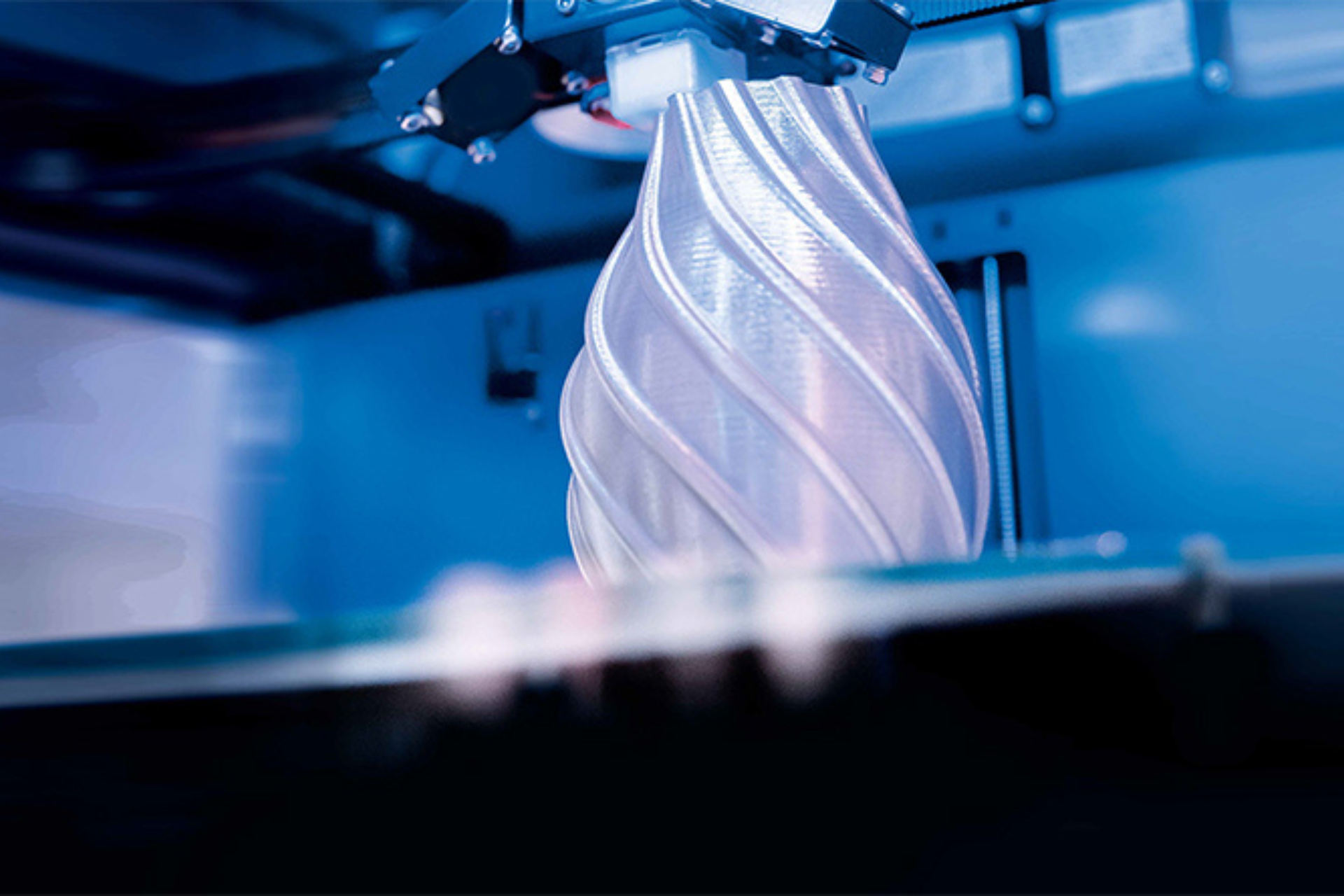

Smoothing / Polishing

Balls - Plastic PA10

Smoothing / Polishing

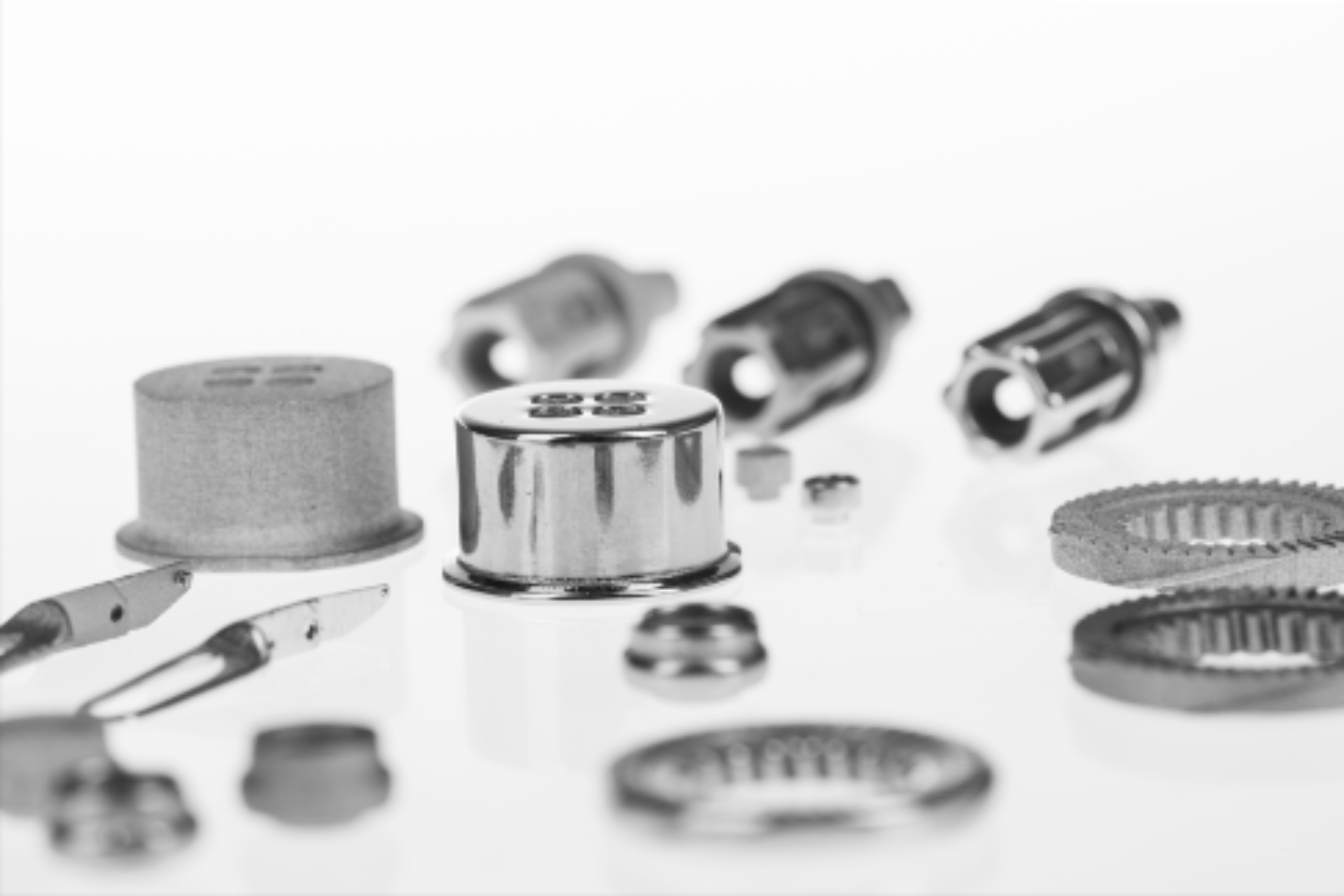

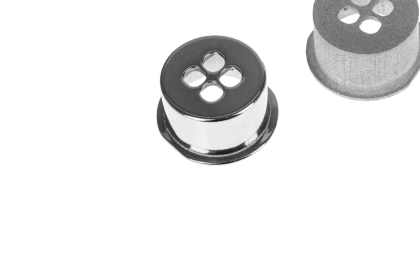

Threading parts - titanium

Smoothing / Polishing

Cranial calvaria - PEI-Ultem

Smoothing / Polishing

Balls - Plastic PA10

Smoothing / Polishing

Threading parts - titanium

Smoothing / Polishing

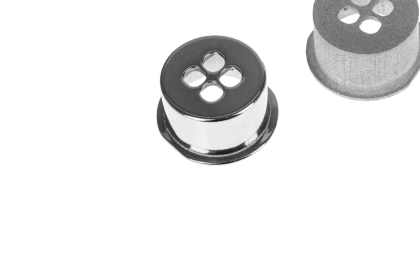

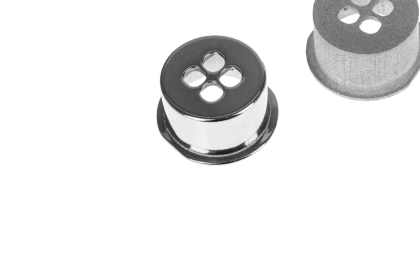

Ear molds - Titanium

Smoothing / Polishing

Ear molds - Titanium

Smoothing / Polishing