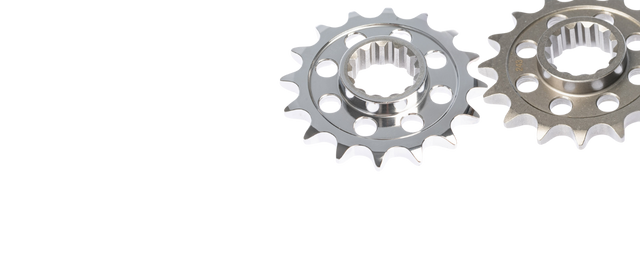

Gears

Smoothing / Polishing

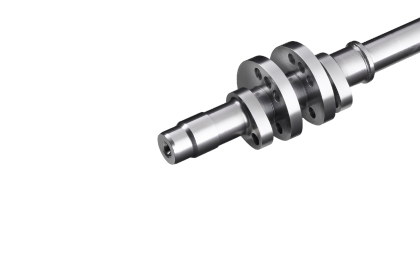

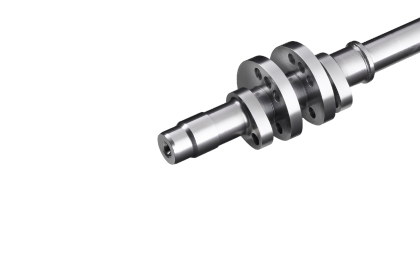

Drive shaft

Smoothing / Polishing

Gears

Smoothing / Polishing

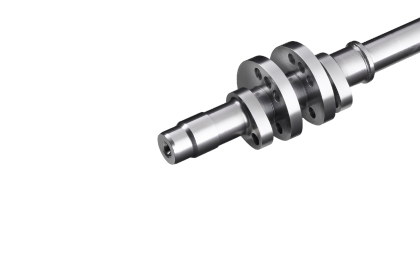

Drive shaft

Smoothing / Polishing

Gearbox parts

Smoothing / Polishing

Gearbox parts

Smoothing / Polishing

Valves

Smoothing / Polishing

Camshaft

Smoothing / Polishing

Gear drum

Smoothing / Polishing

Valves

Smoothing / Polishing

Camshaft

Smoothing / Polishing

Gear drum

Smoothing / Polishing