Drills

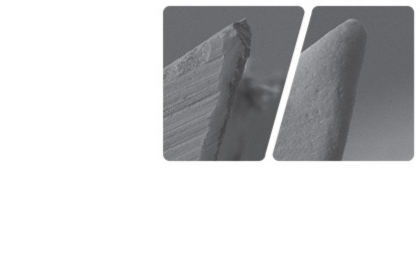

Edge rounding

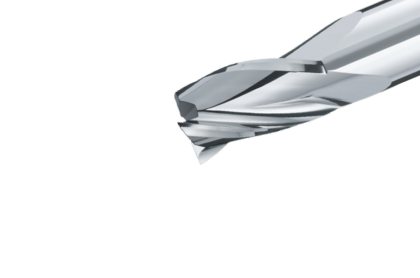

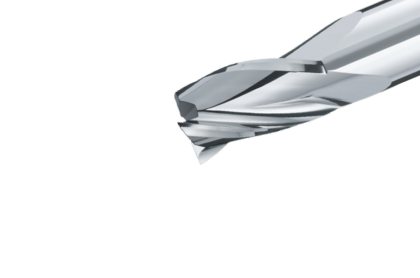

Milling cutter

Polishing

Thread Former

Rounding / Smoothing

Drills

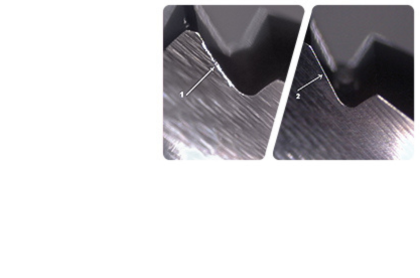

Edge rounding

Milling cutter

Polishing

Thread Former

Rounding / Smoothing

Stamping and deep drawing tools

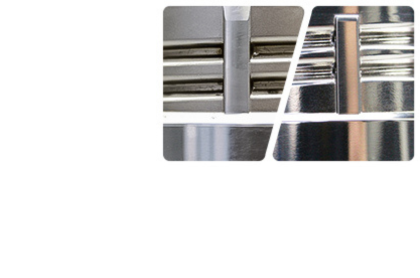

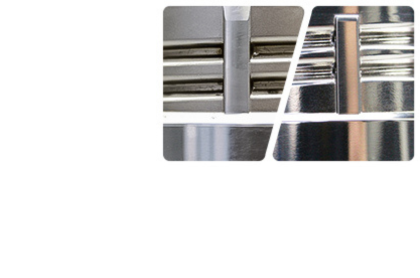

Polishing

Stamping and deep drawing tools

Polishing

Injection molding tools

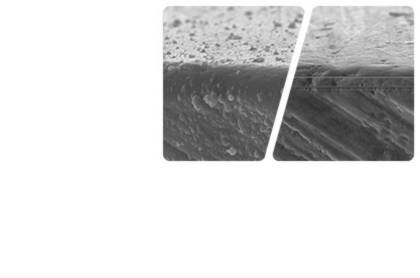

Polishing

Coatings

Smoothing

Steel parts and HSS tools

Deburring

Injection molding tools

Polishing

Coatings

Smoothing

Steel parts and HSS tools

Deburring