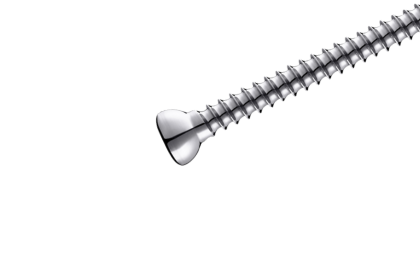

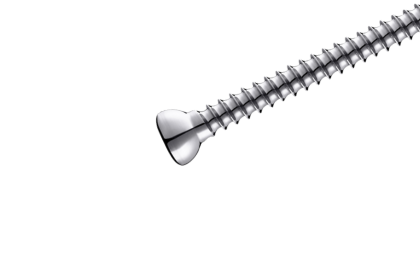

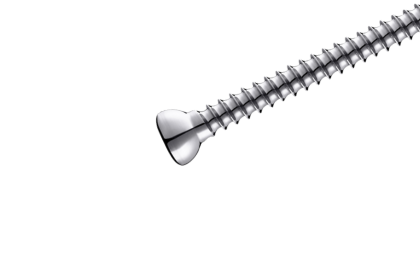

Bone screw

Edge rounding / Smoothing

Hip ball

Smoothing / Polishing

Bone plate

Rounding / Smoothing / Polishing

Bone screw

Edge rounding / Smoothing

Hip ball

Smoothing / Polishing

Bone plate

Rounding / Smoothing / Polishing

Knee joint

Smoothing / Polishing

Knee joint

Smoothing / Polishing

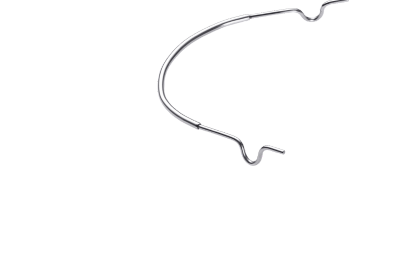

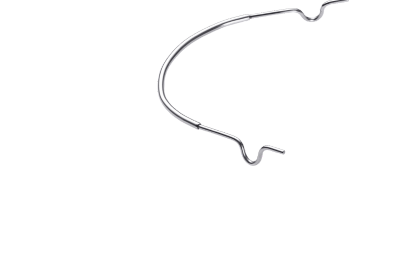

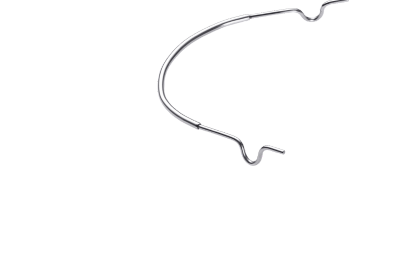

Brackets

Smoothing / Polishing

Medical tool

Smoothing / Polishing

Dental drill

Deburring / Smoothing

Brackets

Smoothing / Polishing

Medical tool

Smoothing / Polishing

Dental drill

Deburring / Smoothing

Hip joint

Smoothing / Polishing

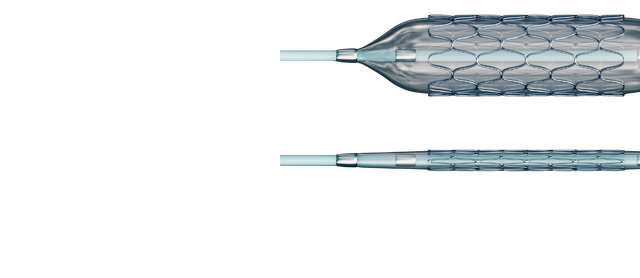

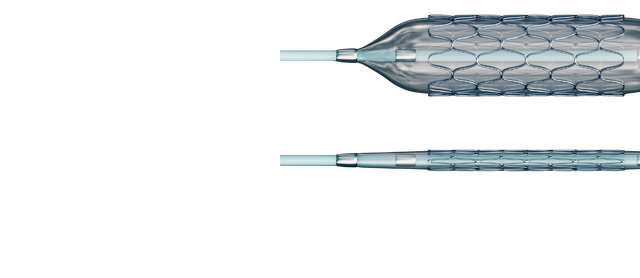

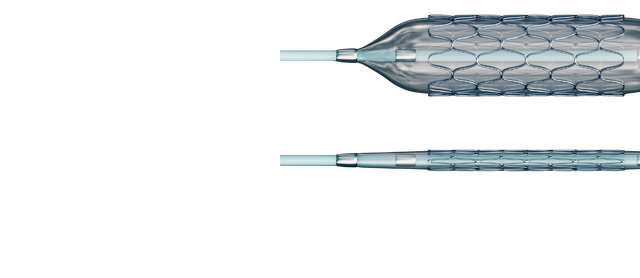

Stents

Deburring / Smoothing

Hip joint

Smoothing / Polishing

Stents

Deburring / Smoothing