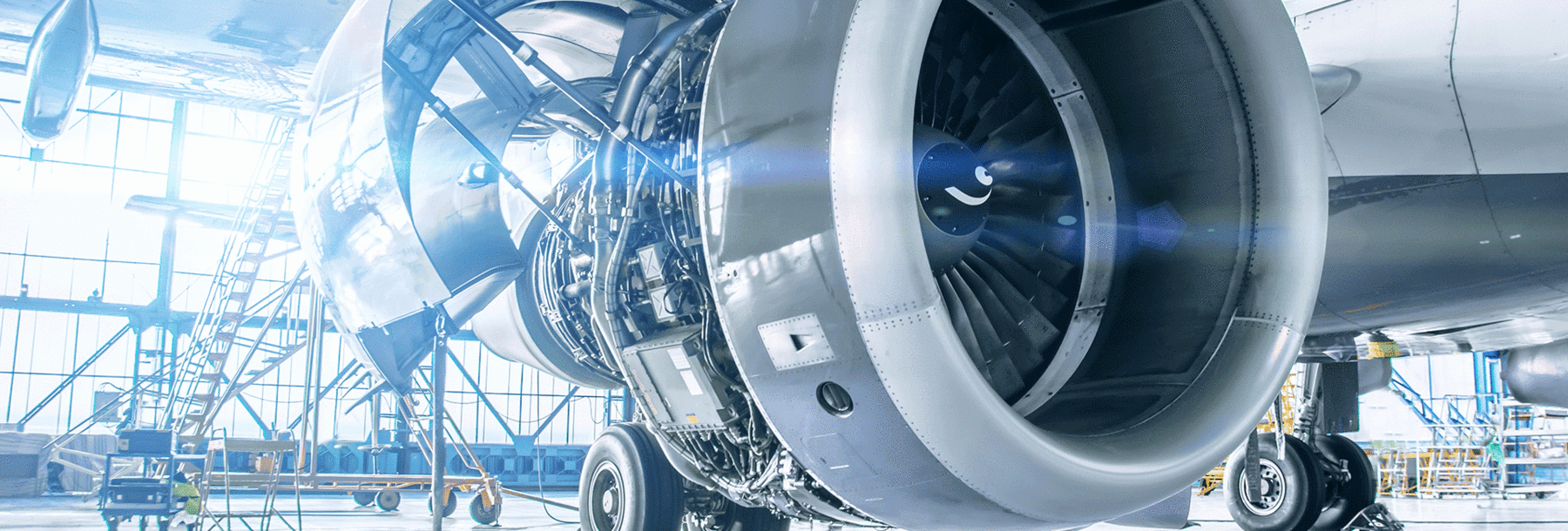

Aerospace

Precision surfaces for maximum aerospace performance.

Precision and reliability are paramount in aerospace engineering, and OFS’s advanced super finishing technology delivers both. With surface smoothing down to Ra 0.04μm and precise edge rounding in a single step, our process ensures optimal performance while preserving component geometry. Trust OFS to meet the industry’s strictest standards with consistent, high-quality results.

Applications

Surface finishing solutions delivering precision and quality for aerospace applications.

Turbine blades

Deburring / Rounding

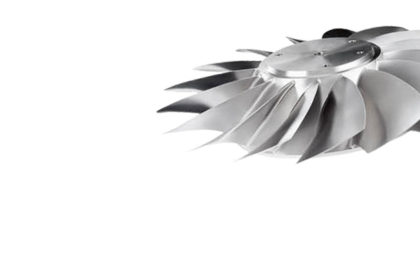

Disc

Deburring / Rounding

Blisk

Smoothing / Polishing

Turbine blades

Deburring / Rounding

Disc

Deburring / Rounding

Blisk

Smoothing / Polishing

Gears

Smoothing / Polishing

Gears

Smoothing / Polishing

Finishing process

benefits

Efficient, reliable finishing with consistent quality, reduced effort, and low-maintenance operation.

- Increased efficiency with reduced friction and extended component service life.

- Versatile application: suitable for milled, blasted, and coated blades, including pre- and post-processing.

- Simultaneous deburring and smoothing for enhanced productivity.

- High output: processes up to 5 parts at once with maximum dimensions of Ø 900 mm, l = 900 mm, m = 200 kg.

- Effective surface leveling, including milling groove smoothing.

- Environmentally friendly and cost-effective process with no hazardous chemicals.

- Enhanced surface quality: improved isotropy, reduced roughness, and minimized wear.

- Precision and versatility: achieves fine geometries while combining deburring, edge rounding, and smoothing in one step.

- Reduced risks: lower chance of lubricant film breakage and micropitting.

Case Studies

Want to know more about OTEC Finishing Services?

Let us know about your requirements and needs, and we will gladly give you more information.